Introduction

As researchers continue to find ways to make the best performing composites as efficient and cost effective as possible, Premold Titanium Mesh has opened up a practical solution for replacing resource-intensive processes by providing a way to deliver superior performance whilst lightweight components required across many industries. Titanium mesh can be used in many different ways and we see the specific properties relating to titanium makes it a game-changing metal in areas from medical engineering to aviation. This paper studies premold titanium mesh as kind of advanced material for firure, thus current performance, technology and applicaions are presented.

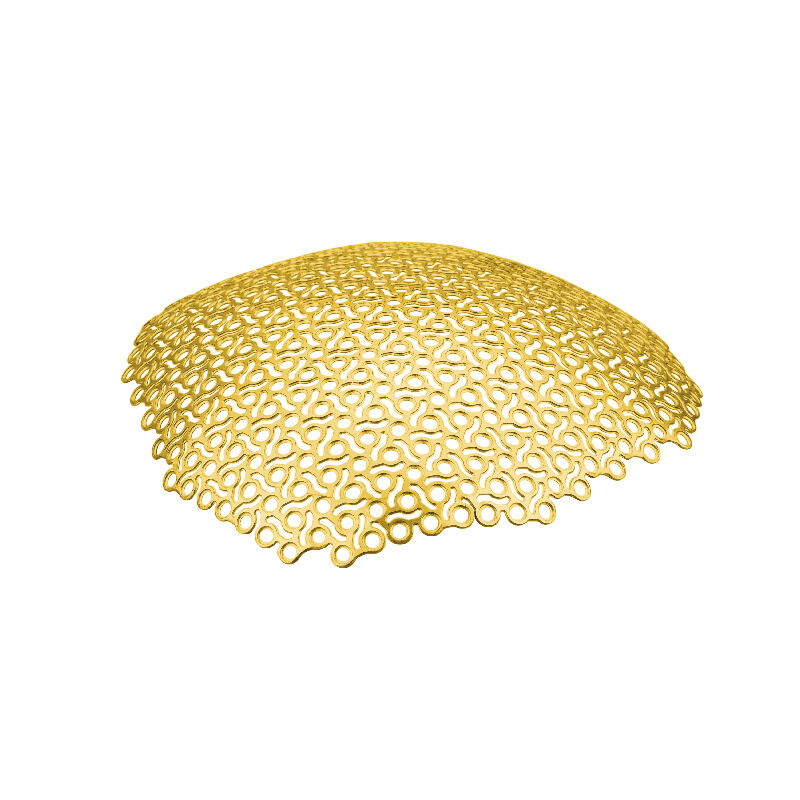

Properties of Titanium Mesh

Titanium mesh is invariably selected as the material due to its high mechanical properties and corrosion resistance outperforming other metals, therefore titanium can be considered as the best choice in severe environments. Titanium has a unique combination of properties, such as its biocompatibility and osseointegration property making it one of the most used metals in many medical applications especially in the field of orthopedics and dentistry. This alone is fortunate because being light merely accomplishes at requirement strength — what titanium mesh does build all while being extremely strong.

Recent Development of Titanium Mesh

As 3D printing and additive manufacturing offer a customizable mesh that can be fabricated with extreme precision for proper fitment into application requirements, titanium metal meshes are becoming desirable. Its technology makes it possible to design titanium mesh of different shapes, thicknesses and degrees of porosity according to the requirements of each individual case. Bioactive coatings have also been developed to impart bone regenerative biological activity on titanium mesh, such as strontium [69] and calcium−phosphorus 70 coatings that enhance functional osteoblast activity.

Applications in Medical Engineering

Moreover, premold titanium mesh becomes a technical niche of medical engineering in the fields of bone augmentation and guided bone regeneration (GBR). Which provides a significant ease of surgical procedures by reducing time and complexity, especially in oral implantology and also alveolar ridge reconstruction. Titanium mesh is deeply established in skeletal restoration of craniofacial and orbital areas; however, due to its premolded nature at opposing the skull model of the patient, it reduces soft tissue injury and lessens recovery period.

Titanium photo functionalization

The innovation in photofunctionalization on titanium mesh as a treatment for limitation due to biocompatibility issue and instability, by keeping biological function. The photofunctionalization of titanium mesh enhances both the adhesion and retention of osteoblasts, thereby benefiting bone grafting and dental implants. This is an indirect one done via first deposited photo responsive molecules which altered their surface characteristics and created a more compatible titanium substrate for cell adhesion/proliferation.

Challenges and Limitations

Titanium mesh has a considerable number of possible benefits; however, the exceptionally high exposure rates in clinical practice have led to efforts to improve specific functional properties and complication profiles. An initial focus is on how the compound interacts upon making sustained contact with a bodily fluid, and some researchers are trying to improve the external surface of meshys that they can be appropriately integrated with native bone. The other problems to be addressed from the industrial point of view include that resonably priced metal of titanium mesh manufacture takes place and special equipment is required for its manipulation.

Future Directions

We are also currently addressing the challenges involved in logistically embedding premold titanium mesh into more complicated bio-smart material, as well as constructs for hard tissue engineering; however, progress is promising. The local therapeutic environment of therapeutic application might further be altered by advances in powerfully modulating phase-sensitive drug delivery systems. The development of 4D printed hierarchical scaffolds with sequential shape morphing properties is continued along with their applications in the field of dynamic structures. In other fields, and by now in medicine as well, such incremental change would be easily imagined.

Conclusion

Titanium meshGiant Nonstick Coated Titanium Mesh Light & StrongSterilizable/biocompatible mesh. High Strength Premold Titanium Mesh High Biocompatibility and all around new opportunities for practically any use light-weight (biocompatible) titanium metal with high power And with continued research and development in the field, it also stands to change everything from healthcare to aerospace. That does point to an exciting few years ahead for premold titanium mesh capability. Some examples would be: Name: Premold titanium meshType: material propertyIn this new historical period, with the rapid growth and development of modern material science and processing technology, a series of new materials. Third example Would illustrate the importance Disclaimer All content on this website gardeshare.com is for informational purposes only.

EN

EN

FR

FR

ES

ES

AR

AR